|

HAU-320 Automatic Butt Splicer |

||

|---|---|---|

| Manufacturer |

|

|

| Features |

- Smart design,almost to meet all customer request - Refined process,without specialized training to operate - Stable tension control system,with piecewise tension coupling method 100% success connect paper - Positive and negative sides of the tape - Can be connected after die cutting and other processing - Automatic unwinding three kinds of die cutting arbitrary choice: manual unwinding mode,winding diameter setting mode and length setting mode - Automatic rewinding with EPC function - The laser positioning paper edge material is aligned |

|

| Model | HAU-320 | HAU-450 |

| Maximum Unwinding Diameter | Φ850 | Φ850 |

| Max.run speed | 100m/min,180m/min | 100m/min,180m/min |

| Unwinding connect paper time | 3 sec | 3 sec |

| Way of connect paper | Oblique connect | Oblique connect |

| Angle of paper connect | 10° | 10° |

| EPC | Digital terminal EPC | Digital terminal EPC |

| Upload material | Manual pressure drawer | Manual pressure drawer |

| Pick up material aligned | Laser positioning | Laser positioning |

| Total Power | 4.5kw | 5.2kw |

| Start run power | 2.2kw | 2.6kw |

| Voltage | 380V | 380V |

| Machine Specifications(LxWxH) | 2650mm×1100mm×2400mm | 2650mm×1350mm×2400mm |

|

SAC-320 Automatic Turret Rewinder |

||

|---|---|---|

| Manufacturer |

|

|

| Features |

- Smart design,almost to meet all customer request - Refined process,without specialized training to operate - Stable tension control system,with piecewise tension coupling method - 100% success connect paper - Automatic unwinding 3 kinds of die cutting arbitrary choice: a) Manual unwinding mode,winding diameter setting mode and finished b) Material and connect paper three mode c) Rewinding with fully automatic EPC function - The laser positioning paper edge material is aligned |

|

| Model | SAC-320 | HAU-450 |

| Maximum Unwinding Diameter | Φ680 | Φ850 |

| Max.run speed | 100m/min,180m/min | 100m/min,180m/min |

| Way of connect paper | Automatic pre-speed paper | Automatic pre-speed paper |

| EPC | Inter-line EPC | Inter-line EPC |

| Way of sliting(optional) | Up and down round knife slitting | Up and down round knife slitting |

| Uploading | Manual unloading part | Manual unloading part |

| Paper core aligned | Laser positioning | Laser positioning |

| Total Power | 4.5kw | 5.2kw |

| Start run power | 2.2kw | 2.6kw |

| Voltage | 380V | 380V |

| Machine Specifications(LxWxH) | 1550mm×1000mmx1650mm | 1550mm×1100mmx1650mm |

|

WBU-320 Automatic Turret Matrix Rewinder |

||

|---|---|---|

| Manufacturer |

|

|

| Features |

Professional for unit type flexographic printing machine online non-stop collect waste developing Cost-effective Winder, can match any of the world flexo presses perfectly - Flexible design - Set up winding diameter automatically, and non-stop rewinding - Convenient automatic inflatable operation |

|

| Model | WBU-320 | WBU-450 |

| Maximum Unwinding Diameter | Φ400 | Φ400 |

| Max.run speed | 180m/min | 180m/min |

| Way of material connect | Automatic pre-speed connection | Automatic pre-speed connection |

| Tension control | Constant pressure automatic | Constant pressure automatic |

| Total Power | 2.5kw | 2.5kw |

| Machine Specifications(LxWxH) | 580mm×1000mm×1800mm | 580mm×1100mm×1800mm |

|

SAC-C380 Automatic 4 Spindles Nonstop Turret Rewinder |

||

|---|---|---|

| Manufacturer |

|

|

|

Features 1. Fully Automatic 4-shafts turret glue type non-stop rewinding machine, the rate of achieving paper success is up to 100%. And it ensures that the tension stability of equipment in the production stage regardless of jog, speed increase, speed reduction, emergency, to realize the best condition of printing machine. 2. The turret type rewinding machine system adopts the world famous brand Bosch Rexroth, which provides intelligent production solutions. It adopts full servo closed-loop tension control and equips with a vibrating plate automatic paper-feeding tube mechanism, a discharge mechanism, to realize online non-stop rewinding. 3. The nonstop rewinder can be connected to rotary die cutting, slitting machines, flexographic printing machines and other equipment. It is equipped with a 1-inch 1.5-inch 3-inch quick release air-expansion shaft. The rewinding machine does not require manual mechanical adjustment when changing the size of different reels, its system automatically adjusts the size of the reel to reduce the labor force for intelligent producti. 4. The fully Automatic turret rewinder with 2 sets glue heating device separately. For the core glue heating device temperature will be 150℃, the tail glue heating device temperature will be lower about 130℃. So will not influence Thermal Paper. For the heating device only need waiting 3-5minutes will Melted hot melt glue. For the use of hot melt glue, we only coat 2 little circle glue on paper core and a little on products tail. So glue cost will be less and our custom glue will not damage the customer print head. |

||

| Technical Specification | |||

|---|---|---|---|

| Model | SAC-C330 | SAC-C380 | SAC-C530 |

| Maximum Rewinding Diameter | 350mm | 350mm | 350mm |

| Max Material Path Width | 330 | 380 | 530 |

| Max Run Speed | 90m/min;120m/min | 90m/min;120m/min | 90m/min;120m/min |

| Minimum Slitting Width | 40mm | 40mm | 40mm |

| Main Machine Size (LxWxH) | 1700mmX1800mmX1800mm | 1700mmX1850mmX1800mm | 1700mmX1900mmX1800mm |

| Machine weight | 2500kg | 2700kg | 3000kg |

| Degree of Automation | Fully Automatic | Fully Automatic | Fully Automatic |

|

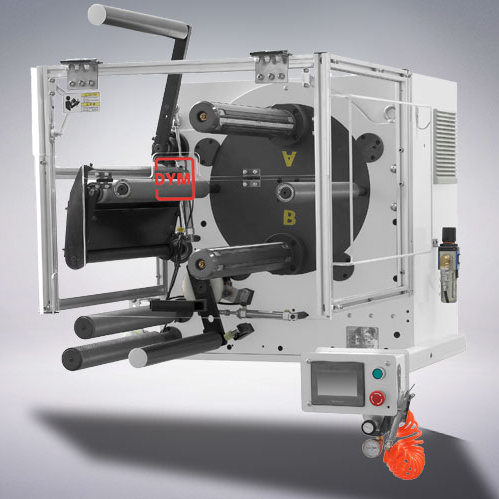

WBC-320 Automatic Overlap Stamping/Laminate Film Nonstop Unwinder |

||

|---|---|---|

| Manufacturer |

|

|

| Features |

1.Equipped with DYM’s efficient tension compensation algorithm 2.One set of overlap platforms, the overlapping is less than 10cm 3.Simple operation, only speed a little time can learn it 4.Can output for very small tensions 5.Can be applied to laminating film, stamping film material 6.Stamping film can be multi mounted at the same time (Optional) 7.Can unwinding two reels different material together and automatic overlap in same time |

|

| Model | WBC-320 | WBC-450 |

| Maximum Unwinding Diameter | Φ400 | Φ400 |

| Max.run speed | 180m/min | 180m/min |

| Way of connect film | Overlap | Overlap |

| EPC | Digital terminal EPC | Digital terminal EPC |

| Pick up material aligned | Laser positioning | Laser positioning |

| Total power | 6kw | 7kw |

| Start run power | 3kw | 3.5kw |

| Voltage | 380V | 380V |

| Machine specifications (L*W*H) | 850mm*1100mm*800mm | 850mm*1200mm*800mm |

|

HAU-B320 Automatic Butt Splicer for Laminate Material |

||

|---|---|---|

| Manufacturer |

|

|

| Features |

- Smart design,almost to meet all customer request - Refined process,without specialized training to operate - Stable tension control system,with piecewise tension coupling method 100% success connect paper - Positive and negative sides of the tape - Can be connected after die cutting and other processing - Automatic unwinding three kinds of die cutting arbitrary choice: a) Manual unwinding mode b) Winding diameter setting mode c) Length setting mode - Automatic rewinding with EPC function - The laser positioning paper edge material is aligned |

|

| Model | HAU-B320 | HAU-B450 |

| Maximum Unwinding Diameter | Φ850 | Φ850 |

| Max.run speed | 180m/min | 180m/min |

| Unwinding connect paper time | 3 sec | 3 sec |

| Way of connect paper | Oblique connect | Oblique connect |

| Angle of paper connect | 10° | 10° |

| EPC | Digital terminal EPC | Digital terminal EPC |

| Upload material | Manual pressure drawer | Manual pressure drawer |

| Pick up material aligned | Laser positioning | Laser positioning |

| Total Power | 4.5kw | 5.2kw |

| Start run power | 2.2kw | 2.6kw |

| Voltage | 380V | 380V |

| Machine Specifications(LxWxH) | 2650mm×1100mm×2400mm | 2650mm×1350mm×2400mm |