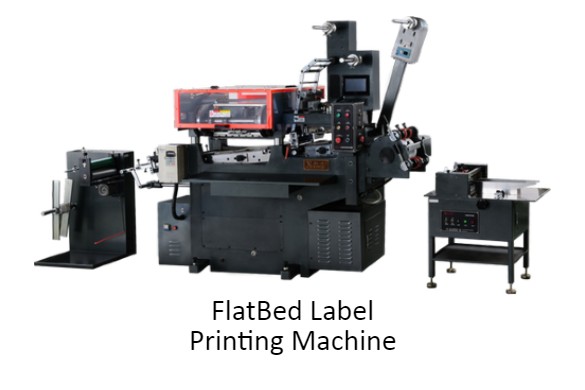

| Details of XinQi Label Printing Machine | ||

|---|---|---|

| Manufacturer |

|

|

| Function | Unwinder-Printing(1-4 color)-Lamination-Die cuter-Waster-Paper sheet cutter or Rewinder | |

| Features |

1. Simple in operation, fast, flexible,accurate in positioning, automatic paper feeding,and consecutive operations of printing, film coating,die cutting and finished products 2. Advanced ink distribution ensures more even coloring 3. Advanced automatic control system to ensure automatic shutdown when there is no more paper, or when the set number of paper counting is reached 4. Slanting back design is employed. Inching contack is employed for printing and die cutting during mechanical action,as a result the pressure is evenly distributed, and clear and spotless printing results can be got whether for large-sized low color or fine characters 5. The built-in centralized oil supply system ensures high-speed operation with low noise and no abrasion 6. the single-phase supply input is employed, thus freeing the equipment from restriction of site motive power configuration |

|

| Model | XQ-L210C | XQ-L260C |

| Printing size-2color(mm) | 200*155 | 250*195 |

| printing size-3color(mm) | 200*100 | 250*126 |

| printing size-4color(mm) | 200*72.5 | 250*92.5 |

| Max.Die-cut size(mm) | 200*200 | 250*230 |

| Max.paper width(mm) | 220 | 260 |

| Max paper length(mm) | 300 | 300 |

| Max.paper speed(/hour) | 12000 | 10000 |

| Machine size(L*M*X) mm | 4000*1400*1700 | 4500*1500*1780 |

| Power(V/Kw) | 220V/2.2KW or 380V/3.7KW | 380V/3.7KW |

| Net weight(Kg) | 2300 | 2800 |

| Basic Configurations |

|---|

|

1. One set of two/three/four-color printing plates, rubber rollers and iron cores respectively 2. One piece of printing platter, upper/lower plate for die cutting respectively 3. One number frame 4.One paper feeding machine and paper cutting machine respectively A standard toolkit |

| Optional configurations need to extra payment |

|---|

|

1.Gold stamp device 2.Rewinding device 3.UV dryer 4.Computer-purpose paper punching device. |